Mitsubishi Electric MSZ-FB50VA Manuel d'installation Page 4

- Page / 4

- Table des matières

- MARQUE LIVRES

Noté. / 5. Basé sur avis des utilisateurs

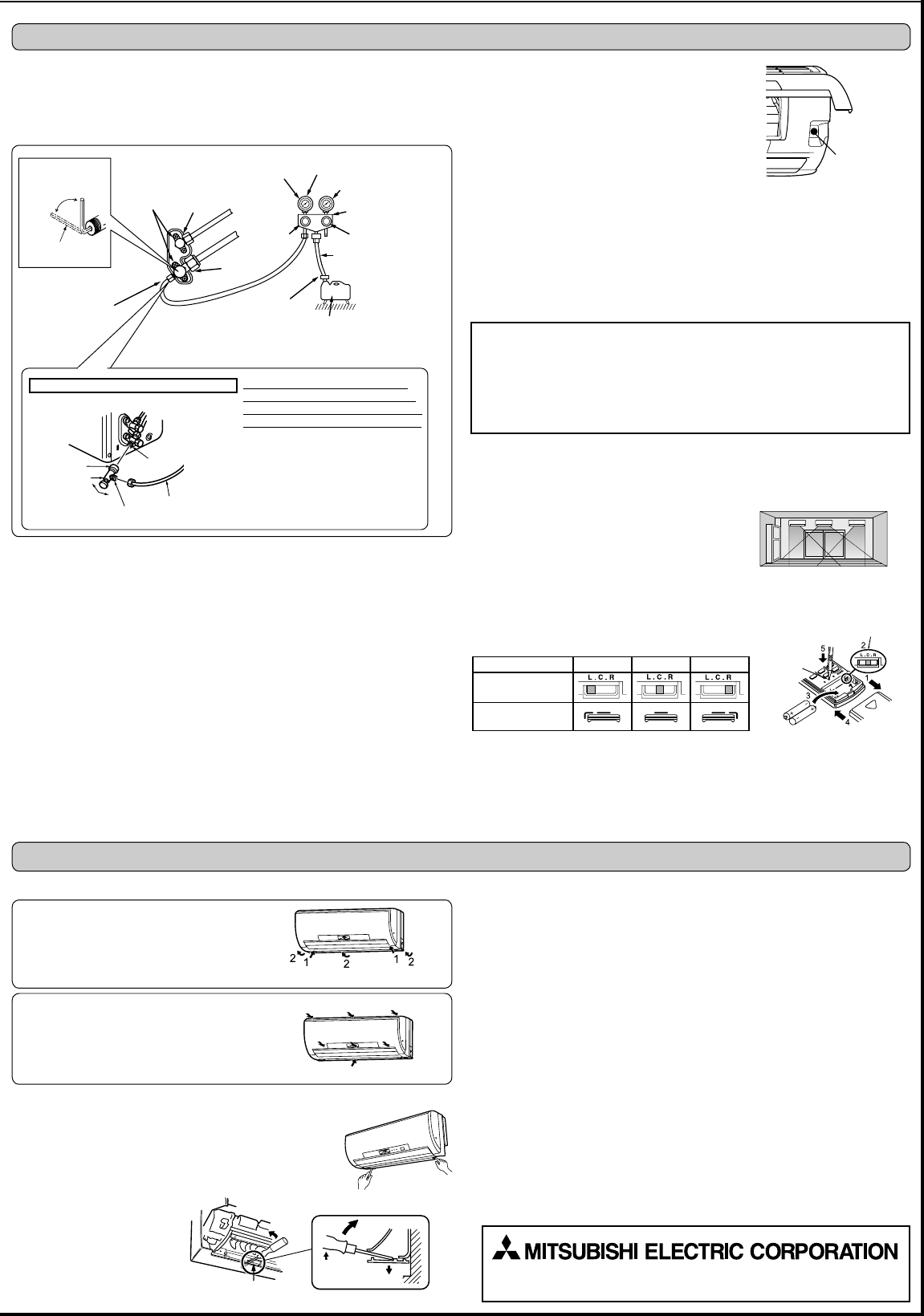

4-1. PURGING PROCEDURES AND LEAK TEST

1) Remove service port cap of stop valve on the side of the outdoor unit gas pipe. (The

VWRSYDOYHZLOOQRWZRUNLQLWVLQLWLDOVWDWHIUHVKRXWRIWKHIDFWRU\WRWDOO\FORVHGZLWKFDS

on.)

2) Connect gauge manifold valve and vacuum pump to service port of stop valve on the

gas pipe side of the outdoor unit.

5-1. REMOVING AND INSTALLING THE PANEL ASSEMBLY

5-3. PUMPING DOWN

:KHQUHORFDWLQJRUGLVSRVLQJRIWKHDLUFRQGLWLRQHUSXPSGRZQWKHV\VWHPIROORZLQJWKH

procedure below so that no refrigerant is released into the atmosphere.

1) Connect the gauge manifold valve to the service port of the stop valve on the gas pipe

side of the outdoor unit.

)XOO\FORVHWKHVWRSYDOYHRQWKHOLTXLGSLSHVLGHRIWKHRXWGRRUXQLW

&ORVHWKHVWRSYDOYHRQWKHJDVSLSHVLGHRIWKHRXWGRRUXQLWDOPRVWFRPSOHWHO\VRWKDW

LW FDQ EH HDVLO\ FORVHG IXOO\ ZKHQ WKH SUHVVXUH JDXJH VKRZV 03D >*DXJH@ NJI

cm

2

).

6WDUWWKHHPHUJHQF\&22/RSHUDWLRQ

To start the HPHUJHQF\RSHUDWLRQ LQ &22/ PRGHGLVFRQQHFW WKH SRZHU VXSSO\ SOXJ

DQGRU WXUQ RII WKH EUHDNHU $IWHU VHFRQGV FRQQHFW WKH SRZHU VXSSO\ SOXJ DQGRU

turn on the breaker, and then press the E.O. SW once. (The HPHUJHQF\&22/

operationFDQEHSHUIRUPHGFRQWLQXRXVO\IRUXSWRPLQXWHV

)XOO\FORVHWKHVWRSYDOYHRQWKHJDVSLSHVLGHRIWKHRXWGRRUXQLWZKHQWKHSUHVVXUH

JDXJHVKRZVWR03D>*DXJH@DSSUR[WRNJIFP

2

).

6) Stop the HPHUJHQF\&22/RSHUDWLRQ

.

Press the E.O. SW twice to stop the operation.

5-2. REMOVING THE INDOOR UNIT

Remove the bottom of the indoor unit from the installation plate.

When releasing the corner part, release both left and right bottom

corner part of indoor unit and pull it downward and forward as

VKRZQLQWKH¿JXUHRQWKHULJKW

If the above method cannot be used

5HPRYHWKHIURQWSDQHO7KHQLQVHUWKH[DJRQDOZUHQFKHVLQWRWKH

square holes on the left and right

sides of the unit and push them

XSDVVKRZQLQWKHIROORZLQJ¿J

-

ure. The bottom of the indoor unit

lowers and releases the hooks.

Removal procedure

5HPRYHWKHVFUHZVZKLFK¿[WKHSDQHODVVHP

-

EO\

5HPRYH WKH SDQHO DVVHPEO\ %H VXUH WR UHPRYH

LWVERWWRPHQG¿UVW

Installation procedure

,QVWDOO WKH SDQHO DVVHPEO\ IROORZLQJ WKH UHPRYDO

procedure in reverse.

%HVXUHWRSUHVVWKHSRVLWLRQVDVLQGLFDWHGE\WKH

DUURZVLQRUGHUWRDWWDFKWKHDVVHPEO\FRPSOHWHO\

to the unit.

Stop valve for

GAS

Stop valve cap

(Torque 19.6 to

29.4 N•m, 200

WRNJIƒFP

Vacuum pump (or the vacuum

pump with the function to

SUHYHQWWKHEDFNÀRZ

Gauge manifold valve

(for R410A)

Compound pressure gauge

(for R410A)

–

0.101 MPa

(

–

760 mmHg)

Handle

Low

Handle High

Adapter for pre-

venting the back

ÀRZ

Charge hose

(for R410A)

*Close

*Open

+H[DJRQDOZUHQFK

Precautions when using the control valve

When attaching the control valve

WRWKHVHUYLFHSRUWYDOYHFRUHPD\

GHIRUPRUORRVHQLIH[FHVVSUHVVXUH

LVDSSOLHG7KLVPD\FDXVHJDVOHDN

Service port

Charge hose

%RG\

Close

Open

Control valve

A

When attaching the control valve to

the service port, make sure that the

valve core is in closed position, and

then tighten part A. Do not tighten

SDUW$RUWXUQWKHERG\ZKHQYDOYH

core is in open position.

Service port cap

(Torque 13.7 to

17.7 N•m, 140 to

180 kgf•cm)

*4 to 5 turns

3) Run the vacuum pump. (Vacuumize for more than 15 minutes.)

4) Check the vacuum with gauge manifold valve, then close gauge manifold valve, and

stop the vacuum pump.

5) Leave as it is for one or two minutes. Make sure pointer gauge manifold valve remains

LQWKHVDPHSRVLWLRQ&RQ¿UPWKDWSUHVVXUHJDXJHVKRZV±03D>*DXJH@±

mmHg).

5HPRYHJDXJHPDQLIROGYDOYHTXLFNO\IURPVHUYLFHSRUWRIVWRSYDOYH

$IWHUUHIULJHUDQWSLSHVDUHFRQQHFWHGDQGHYDFXDWHGIXOO\RSHQDOOVWRSYDOYHVRQERWK

VLGHVRIJDVSLSHDQGOLTXLGSLSH2SHUDWLQJZLWKRXWIXOO\RSHQLQJORZHUVWKHSHUIRUP

-

ance and this causes trouble.

8) Refer to 1-3., and charge the prescribed amount of refrigerant if needed. Be sure to

FKDUJH VORZO\ ZLWK OLTXLG UHIULJHUDQW 2WKHUZLVH FRPSRVLWLRQ RI WKH UHIULJHUDQW LQ WKH

V\VWHPPD\EHFKDQJHGDQGDIIHFWSHUIRUPDQFHRIWKHDLUFRQGLWLRQHU

9) Tighten cap of service port to obtain the initial status.

10) Leak test

4-2. TEST RUN

,QVHUWSRZHUVXSSO\ SOXJLQWRWKHSRZHURXWOHWDQGRUWXUQRQWKHEUHDNHU &KHFNWKDW

DOO/('ODPSVDUHQRWOLW,IWKH\DUHEOLQNLQJFKHFNWKDWWKHKRUL]RQWDOYDQHLVLQVWDOOHG

FRUUHFWO\5HIHUWRRSHUDWLQJLQVWUXFWLRQVIRUGHWDLOV

2) Press the E.O. SW once for

COOL, and twice for HEAT operation. Test run will be per-

IRUPHGIRUPLQXWHV,IWKHRSHUDWLRQLQGLFDWRUEOLQNVHYHU\VHFRQGVLQVSHFWWKH

LQGRRURXWGRRUXQLW FRQQHFWLQJ ZLUH $ IRUPLVZLULQJ $IWHU WKHWHVW UXQ HPHUJHQF\

Stop valve

for LIQUID

Caution:

• After test run or remote signal reception check, turn off the unit with the E.O. SW or

WKHUHPRWHFRQWUROOHUEHIRUHWXUQLQJRIIWKHSRZHUVXSSO\1RWGRLQJVRZLOOFDXVHWKH

XQLWWRVWDUWRSHUDWLRQDXWRPDWLFDOO\ZKHQSRZHUVXSSO\LVUHVXPHG

To the user

$IWHULQVWDOOLQJWKHXQLWPDNHVXUHWRH[SODLQWKHXVHUDERXWDXWRUHVWDUWIXQFWLRQ

,I DXWR UHVWDUW IXQFWLRQ LV XQQHFHVVDU\ LW FDQ EH GHDFWLYDWHG &RQVXOW WKH VHUYLFH

representative to deactivate the function. Refer to the service manual for details.

Push

Lower

Square hole

4. PURGING PROCEDURES, LEAK TEST, AND TEST RUN

Pressure gauge

(for R410A)

5. RELOCATION AND MAINTENANCE

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO

100-8310, JAPAN

4-5. EXPLANATION TO THE USER

8VLQJWKH23(5$7,1*,16758&7,216H[SODLQWRWKHXVHUKRZWRXVHWKHDLUFRQGL-

WLRQHUKRZWRXVHWKHUHPRWHFRQWUROOHUKRZWRUHPRYHWKHDLU¿OWHUVKRZWRUHPRYH

or put the remote controller in the remote controller holder, how to clean, precautions

for operation, etc.)

5HFRPPHQGWKHXVHUWRUHDGWKH23(5$7,1*,16758&7,216FDUHIXOO\

Set the slide switch of the remote controller according to the installed position of the

LQGRRUXQLW,IWKHVZLWFKLVQRWVHWFRUUHFWO\WKHDLUFRQGLWLRQHUPD\QRWIXQFWLRQSURSHUO\

Installation position:

Left: Distance to objects (wall, cabinet, etc.) is less

than 50 cm to the left

Center: Distance to objects (wall, cabinet, etc.) is

more than 50 cm to the left and right

Right: Distance to objects (wall, cabinet, etc.) is less

than 50 cm to the right

4-4. REMOTE CONTROLLER SETTING

1) Remove the front lid.

2) Set the slide switch according to the installed position of the indoor unit.

3) Insert two (AAA) batteries.

4) Reattach the front lid.

3UHVVWKH5(6(7EXWWRQJHQWO\XVLQJDWKLQVWLFN

Installation position Left Center Right

Slide switch

Remote controller

GLVSOD\

(Left) (Center)(Right)

RESET

button

SLIDE SWITCH

(PHUJHQF\

operation switch

(E.O. SW)

mode (set temperature 24ºC) will start.

3) To stop operation, press the E.O. SW several times

until all LED lamps turn off. Refer to operating instruc-

tions for details.

Checking the remote (infrared) signal reception

Press the ON/OFF button on the remote controller (6)

and check that an electronic sound is heard from the

indoor unit. Press the ON/OFF button again to turn the air

conditioner off.

• Once the compressor stops, the restart preventive de

-

vice operates so the compressor will not operate for 3

minutes to protect the air conditioner.

4-3. AUTO RESTART FUNCTION

7KLVSURGXFWLVHTXLSSHGZLWKDQDXWRUHVWDUWIXQFWLRQ:KHQWKHSRZHUVXSSO\LVVWRSSHG

GXULQJRSHUDWLRQVXFKDVGXULQJEODFNRXWVWKHIXQFWLRQDXWRPDWLFDOO\VWDUWVRSHUDWLRQLQ

WKHSUHYLRXVVHWWLQJRQFHWKHSRZHUVXSSO\LVUHVXPHG5HIHUWRWKHRSHUDWLQJLQVWUXF

-

tions for details.)

(540 pages)

(540 pages)

(104 pages)

(104 pages)

Commentaires sur ces manuels